Tin Zinc alloy wire Sn70Zn30

- Typ płatności:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Czas dostawy:

- 15 Dni

- Transport:

- Ocean, Land, Air

- Port:

- SHANGHAI, NINGBO

Your message must be between 20 to 2000 characters

Contact Now| Miejsce pochodzenia: | SHAOXING,CHINA |

|---|---|

| Wydajność: | 60TON PER MONTH |

| Możliwości dostaw: | 120TON PER MONTH |

| Typ płatności: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certyfikat: | ISO9001 |

| Kodeks HS: | 80030000 |

| Transport: | Ocean,Land,Air |

| Port: | SHANGHAI,NINGBO |

Product Introduction:

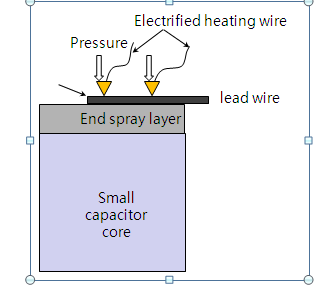

Zinc wire can be used in the big capacitance, But the small capacitor (DC)is different from that of the large capacitance. Usually select the tin and zinc alloy wire to welding.The lead welding of the small capacitance is usually done by applying certain pressure to the lead placed on the surface of the spray layer. At the same time, the lead wire can be heated and the material near the lead wire will be melted by electricity, so that the welding of the lead wire and the spray layer can be realized after cooling. For the welding method of small capacitance, if the pure zinc spray is used, the melting temperature is ~ 420 ℃, it is easy to burn the plastic film and make the capacitor scrap, so it is necessary to use the gold spray material with low melting point.

1.Features:

1. Low melting point, environmental protection

2.The surface is bright

3. The contents of Tin may be within the range of 20-90%

4. The bonding ability of the bottom layer spraying material and the evaporating coating metal

5, The bonding ability of the welding layer gold spraying material and the lead wire

6. The bonding ability between the bottom layer and the welding layer

2.Chemical composition

|

Specification |

Main Ingredient% |

Impurity %≤ |

||||

|

Sn |

Zn |

Pb |

Cd |

Fe |

Total |

|

|

HYSnZn10 |

89-91 |

9-11 |

0.04 |

0.002 |

0.012 |

0.05 |

|

HYSnZn15 |

84-86 |

14-16 |

0.04 |

0.002 |

0.012 |

0.05 |

|

HYSnZn20 |

79-81 |

19-21 |

0.04 |

0.002 |

0.012 |

0.05 |

|

HYSnZn30 |

69-71 |

29-31 |

0.04 |

0.002 |

0.012 |

0.05 |

3. Mechanical characteristics

|

Tensile Strength |

≥70 |

|

Elongation After Rupture |

≥20 |

|

Specific Gravityg/cm3 |

7.0-7.3 |

|

Specific resistance(mΩ.mm2/m)at20℃ |

≤95-115 |

|

Solidus/Liquidus Temp.(℃) |

198-325 |

Related Keywords